Press brake forming leverages a powerful process to precisely shape metal panels into intricate and complex structures. The process comprises bending sheet metal between dies, which form the desired profile. This robust method is ideal for producing a wide variety of metal panels, from simple housings to complex enclosures.

Precision press brake forming offers numerous perks, including high accuracy, repeatability, and the ability to work with multitude metal thicknesses and alloys.

Moreover, this process is known for its speed, making it a popular choice in industries such as automotive.

Mastering the Art of Panel Bending with Hydraulic Machines

Panel bending leverages hydraulic machines to craft sheet metal into accurate curves and angles. This flexible process facilitates the manufacture of a wide variety of products, from automotive components to building materials. Achieving this art form demands a solid understanding of hydraulic principles, panel material properties, and bending techniques.

- Expert operators can control the intensity exerted by the hydraulic system to achieve specific bend radii and angles.

- Meticulous tool setup and workpiece clamping are vital for producing high-quality bends that meet production standards.

- Security protocols must be meticulously followed when operating hydraulic machinery to prevent injury.

With training, individuals can hone their skills in panel bending, becoming valuable assets to any fabrication shop.

Precise Sheet Metal Fabrication: The Power of Bending Machines

In the realm of sheet metal fabrication, bending machines stand as indispensable powerhouses, enabling manufacturers to mold flat sheets into intricate three-dimensional components. These versatile tools leverage hydraulic pressure to precisely bend sheet metal, achieving complex angles and radii with remarkableaccuracy. From automotive parts to aerospace structures, bending machines play a essential role in shaping the world around us.

The power of bending machines lies in their potential to produce high-quality bends with minimal material waste. Cutting-edge designs incorporate computer-controlled systems, increasing production efficiency and reducing the need for manual intervention. This level of automation allows for precise repeatability, ensuring that every bend meets stringent quality standards.

Techniques to Press Brake Operations

Want to form metal like a skilled? Mastering press brake operations unlocks potential for creating accurate bends. First, understand the fundamentals of sheet metal thickness and gauge. Then, select the right die set for your specific task. Remember to adjust your material carefully before operating the press brake. With practice and attention to detail, you can manufacture top-notch bends every time.

- Always be safe. Wear appropriate personal protective equipment.

- Scheduled servicing is crucial for smooth operation and quality results.

- Seek training to become proficient in press brake operations.

Streamlined Machine Bending for High-Volume Production

In the realm of high-volume manufacturing, efficiency reigns supreme. Programmable machine bending has emerged as a vital process for producing significant quantities of metal with precision get more info and speed. These advanced machines execute intricate bending operations efficiently, eliminating the need for manual labor and reducing the potential for human error.

- Benefits of automated machine bending include increased production output, enhanced accuracy, reduced expenses, and greater consistency in product quality.

- Sectors such as automotive, aerospace, construction, and electronics heavily rely on automated machine bending to fabricate complex metal structures and components.

The integration of these machines into manufacturing processes has transformed the landscape of high-volume production, enabling businesses to meet needs with greater efficiency and cost-effectiveness.

Enhance Your Workflow: Choosing the Right Bending Equipment

When it comes to achieving optimal efficiency in your workflow, selecting the appropriate bending equipment is fundamental. A wide range of options are available on the market, each tailored to unique applications and material types. Consider factors such as the volume of your bending needs, the profile of the materials you'll be working with, and the required degree of bend. By carefully analyzing these aspects, you can identify the bending equipment that best suits your requirements, ultimately boosting your overall workflow.

- Hydraulic bending brakes offer flexibility for a range of bending tasks.

- Computerized bending machines provide high accuracy for complex shapes.

- Shearing equipment is ideal for creating smooth, consistent bends in sheet metal.

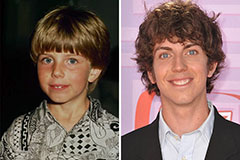

Taran Noah Smith Then & Now!

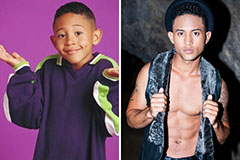

Taran Noah Smith Then & Now! Tahj Mowry Then & Now!

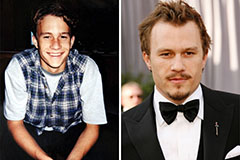

Tahj Mowry Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!